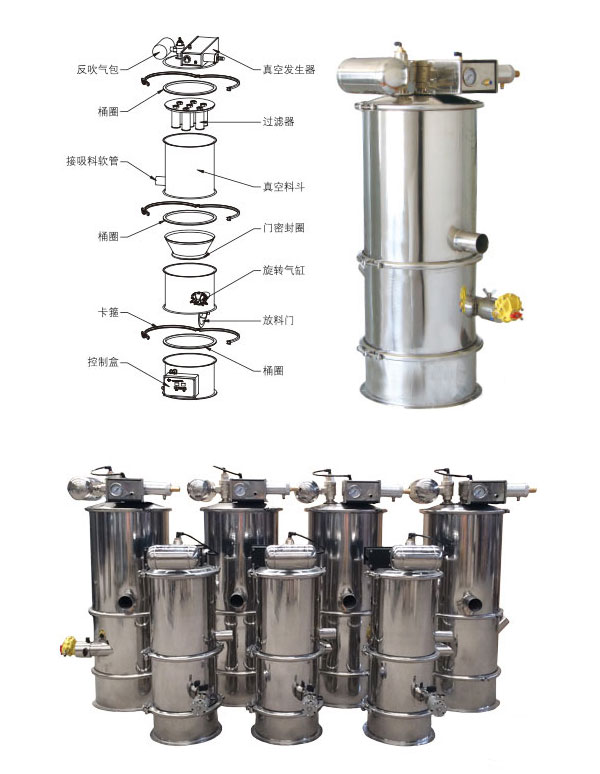

Vacuum feeder is a vacuum feeding machine by using pneumatic vacuum pump as vacuum source. With this vacuum feeder materials could be fed directly from container into mixer, reactor, hopper, sheet press, packing machine, vibrating griddle, pellet trimming machine, hydro-state pelleter, dry-state pelleter and disintegrator. To use this feeder could lighten workers’ labor intensity, put an end to powder pollution and ensure that the production process meets GMP requirements.

When “ON/OFF” key is pressed, compressed air gets into vacuum pump and the discharge of the hopper, driven by pneumatic cylinder, is closed, vacuum is established in hopper. Vacuum feeder will form an air current under vacuum. Operated by this air current, material is fed to vacuum hopper via hose. After a period of time (feeding time, adjustable) compressed air is cut off, pneumatic vacuum pump could not generate vacuum and the discharge of the hopper, driven by pneumatic cylinder, gets open, the vacuum in vacuum feeder disappears, and material is automatically discharged from the discharge into the receiving machine (such as sheet press and packing machine). Meanwhile, the compressed air stored in the air tank blows the filter in reverse to make the filter cleaned automatically. After a period of time (discharge time, adjustable) compressed air is restarted, pneumatic vacuum pump generates vacuum, discharge is closed, vacuum feeder feeds material again, in this way the feeder works in cycles to make the material fed into receiving machine continuously.

For the vacuum feeder with material level control automatic feeding is realized with the hopper of the material-receiving machine through material level control. When the material level is higher than a position in the hopper of the material-receiving machine, vacuum feeder stops feeding, but when he material level is lower than a position in the hopper, vacuum feeder starts feeding automatically. And feeding on the material-receiving machine is thus completed.

1. Compressed air should be oil-free and water-free.

2. The feeding capacity has been determined with a 3 meter feeding distance.

3. The feeding capacities are greatly different with different materials.

When “ON/OFF” key is pressed, compressed air gets into vacuum pump and the discharge of the hopper, driven by pneumatic cylinder, is closed, vacuum is established in hopper. Vacuum feeder will form an air current under vacuum. Operated by this air current, material is fed to vacuum hopper via hose. After a period of time (feeding time, adjustable) compressed air is cut off, pneumatic vacuum pump could not generate vacuum and the discharge of the hopper, driven by pneumatic cylinder, gets open, the vacuum in vacuum feeder disappears, and material is automatically discharged from the discharge into the receiving machine (such as sheet press and packing machine). Meanwhile, the compressed air stored in the air tank blows the filter in reverse to make the filter cleaned automatically. After a period of time (discharge time, adjustable) compressed air is restarted, pneumatic vacuum pump generates vacuum, discharge is closed, vacuum feeder feeds material again, in this way the feeder works in cycles to make the material fed into receiving machine continuously.

For the vacuum feeder with material level control automatic feeding is realized with the hopper of the material-receiving machine through material level control. When the material level is higher than a position in the hopper of the material-receiving machine, vacuum feeder stops feeding, but when he material level is lower than a position in the hopper, vacuum feeder starts feeding automatically. And feeding on the material-receiving machine is thus completed.

Technical Specification

|

Model |

QVC-1 |

QVC-2 |

QVC-3 |

QVC-4 |

|

Feeding volume |

350L/h |

700L/h |

1500L/h |

3000L/h |

|

Hopper volume |

1.1L |

6.0L |

12L |

42L |

|

Air Consumption |

180L/min |

360L/min |

720L/min |

1440L/min |

|

Pressure of Air |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

0.5-0.6Mpa |

|

Overall dimension |

Φ140*626 |

Φ213*622 |

Φ290*852 |

Φ420*1208 |

2. The feeding capacity has been determined with a 3 meter feeding distance.

3. The feeding capacities are greatly different with different materials.